Steam separator "SP-25" DN125, PN16

Monastyrishchensky plant of boiler equipment "Energometmash" offers a centrifugal steam separator "SP-25" of its own production with a connecting diameter of DN125 and a body pressure of PN16.

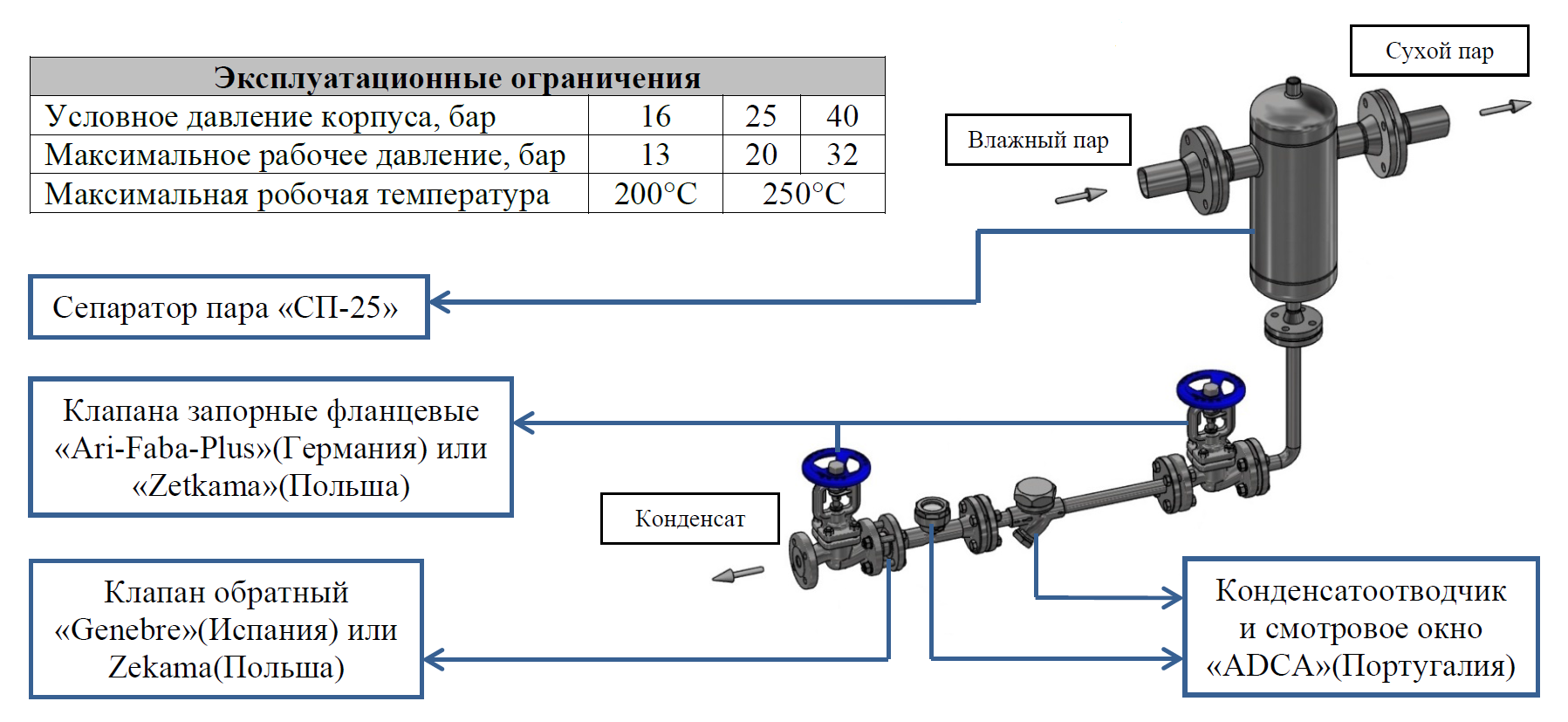

Separators SP-25 of centrifugal type are designed to trap and remove liquid droplets that are in steam in order to obtain high-quality (dry) steam. They are especially recommended for installation on main steam pipelines in front of pressure reducers and other control devices, as well as flow meters. Installing a separator completely eliminates the transmission of water hammer. Also suitable for removing condensate in compressed air systems.

The condensate formed as a result of separation is removed through the drain pipe of the separator using a condensate drain unit.

It is recommended to select the separator diameter equal to the steam pipeline diameter. It has a bottom threaded (optionally flanged) hole for connecting a condensate drain unit and an upper hole for connecting an air vent.

PRINCIPLE OF OPERATION:

When steam or compressed air enters the separator, particles with a high specific gravity such as water and oil droplets are separated as a result of centrifugal impact forces and the effect of rotation Moisture in suspensions Dirt and film

APPLICATION: Steam, compressed air, gases

DIMENSIONS: DN15...DN300

CONNECTION: flange according to GOST 12821-80

INSTALLATION:

- Mounting position - horizontal with drain pipe down.

- The resulting condensate is removed through the drain pipe of the separator using the condensate drain unit.

MATERIALS: carbon steel (stainless steel on request).

SIZING: It is recommended to select the separator diameter equal to the steam line diameter. Separator pressure losses can be neglected at the recommended optimum travel speeds. Steam speed is optimal - 20-40 m/s, minimum - 15 m/s.

| It is recommended to install steam separators not only in front of the process equipment, but also in front of the control valves of steam systems (direct-acting temperature controller, steam pressure controller, air pressure controller, electric control valve, etc.). Also, centrifugal steam separators (cyclone-type steam separator) are installed in front of plate heat exchangers, shell-and-tube heat exchangers, flow meters, etc. Main benefits of using steam separators SP-25:

|

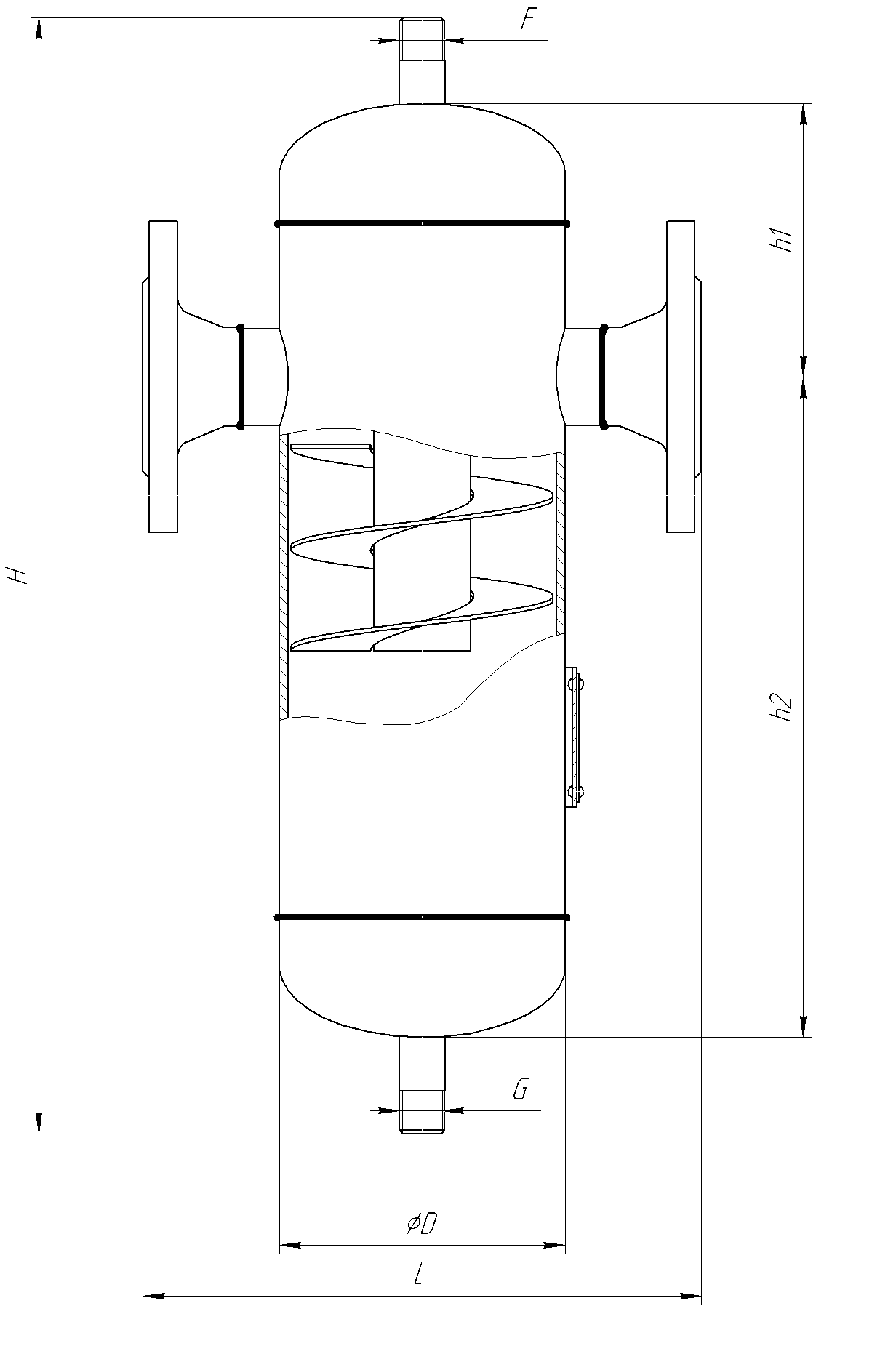

Overall dimensions of steam separator "SP-25"

| DN | Overall dimensions, mm | Volume * , dm 3 | Weight**, kg | ||||||

| OD | H | h1 | h2 | L | F | G | |||

| fifteen | 114 | 345 | 83 | 177 | 230 | ½" | 2.1 | 5.3 | |

| twenty | 114 | 365 | 91 | 189 | 230 | 2.3 | 6.0 | ||

| 25 | 114 | 385 | 100 | 200 | 230 | 2.5 | 6.8 | ||

| 32 | 133 | 505 | 122 | 298 | 260 | 4.9 | 10.4 | ||

| 40 | 133 | 545 | 127 | 333 | 260 | 5.5 | 11.7 | ||

| fifty | 168 | 590 | 142 | 363 | 310 | 9.6 | 18.0 | ||

| 65 | 219 | 626 | 162 | 388 | 380 | ¾" | 17.4 | 33.7 | |

| 80 | 219 | 686 | 170 | 440 | 400 | 19.8 | 39.1 | ||

| 100 | 273 | 791 | 190 | 525 | 485 | 36.5 | 55.5 | ||

| 125 | 325 | 872 | 215 | 585 | 535 | one" | 57.7 | 86.1 | |

| 150 | 377 | 972 | 250 | 650 | 585 | 87.2 | 127.0 | ||

| 200 | 426 | 1172 | 285 | 815 | 605 | 139.6 | 185.0 | ||

* The volume is indicated for PN16, for PN25 and PN40 the volume may be less.

** Weight corresponds to PN16.

F, G - threaded drain hole in the standard version. It is possible to make a drainage hole with a flanged connection. The hole on top for installing the air vent is equal to the drain hole.