MTKU-1.4 (fuel: gas/liquid) 2.0 t. steam/hour

Plant "ENERGOMETMASH" offers Modular transportable boiler plant "MTKU-1.4(P)" of its own production with a steam capacity of 2.0 tons of steam / hour, which is designed for technological steam supply, as well as for heating water for heating and hot water supply systems. The boiler room is made on the basis of two steam boilers of the "E" series for operation on gaseous or liquid fuels.

This boiler plant does not require project development , as it is manufactured according to the agreed specifications of Energometmash LLC TU U 25.3-36350685-001:2014 . To install a boiler house on the ground, it is only necessary to complete a project for supplying external communications (water, electricity, sewerage, etc.).

This boiler plant is made on the basis of two or three easily assembled transportable modules. Three modules are provided if the boiler room is equipped with an atmospheric vertical type deaerator DA-3.

MAIN ADVANTAGES:

- it is not required to develop a full-fledged boiler house project, which increases the cost and construction time. It is only necessary to complete the project for supplying external communications;

- if necessary, the boiler room can be easily transferred to another facility;

- low payback periods;

- small overall dimensions;

- Ability to start immediately after installation

FUEL FUEL AND BURNER USED

CIBITAL UNIGAS(ITALY), WEISHAUPT(GERMANY):

- gaseous: natural and liquefied gas;

- liquid: M100 fuel oil, diesel fuel, domestic stove fuel;

Automatic burners CIBITAL UNIGAS (Italy) and WEISHAUPT (Germany) are a set of equipment manufactured by leading world manufacturers, necessary for the safe process of fuel combustion in a boiler or any other heat generator. The cost of the burners includes the burner body, fan with electric motor, electrical panel with automation, ignition transformer, electrodes, fuel supply equipment - electromagnetic gas valves, or a pump with an electric motor for supplying liquid fuel.

The automatic mode of operation of these burners ensures reliable and economical operation of the E-series steam boilers.

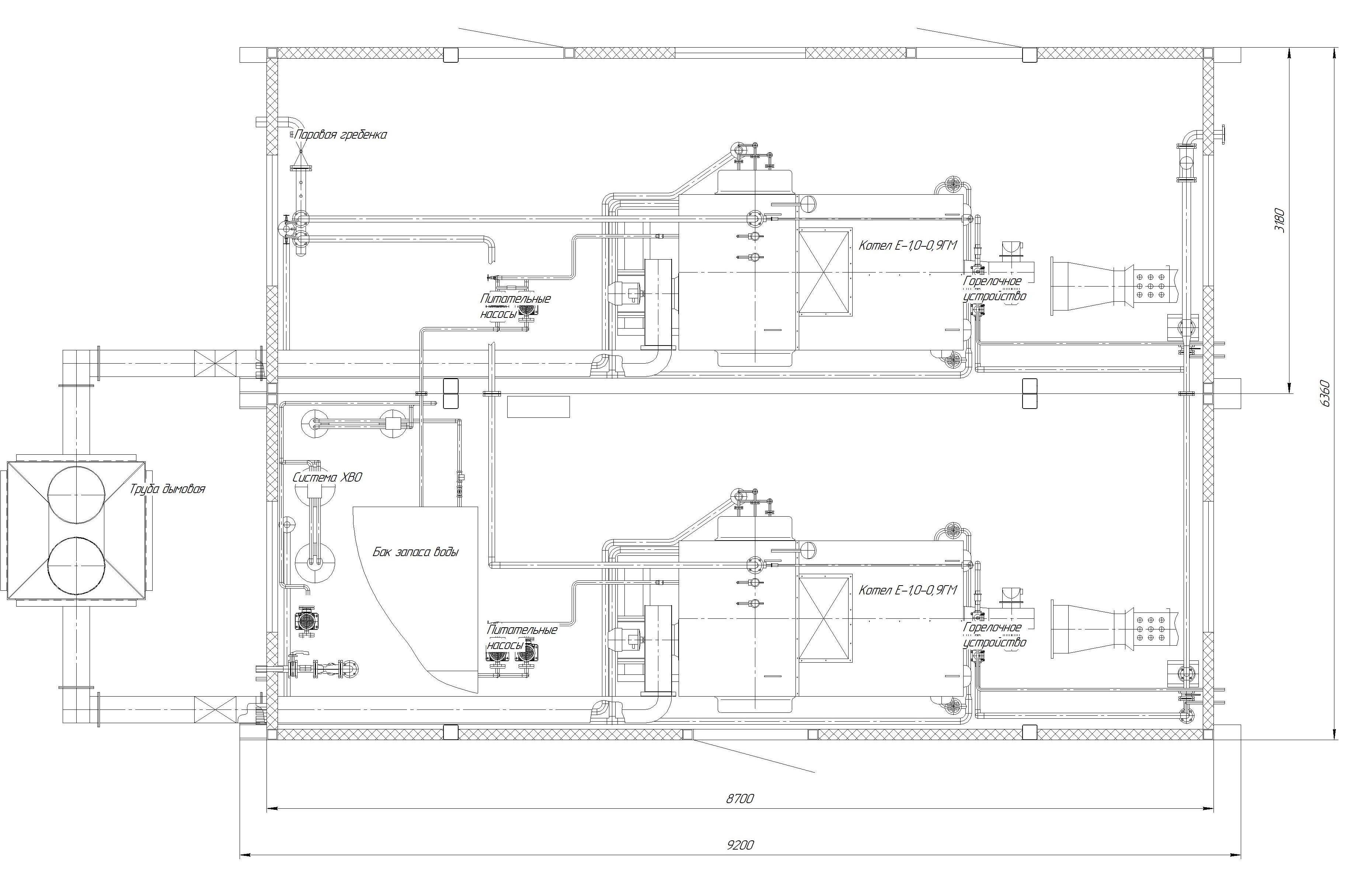

Plan-scheme of a modular transportable boiler plant based on

two steam boilers E-1.0-0.9GM (fuel-liquid, gaseous)

THERMAL POINT

Additionally, heat points with collapsible plate heat exchangers for heating individual branches of the heating system and hot water supply can be located in the boiler room, consisting of:

- collapsible lamellar heat exchangers Sondex (Denmark);

- network, circulation and make-up pumps Wilo (Germany);

- locking and regulating and safety fittings Ari-Armaturen (Germany) ;

- automation to maintain a given temperature schedule, instrumentation;

- waste heat accounting systems based on heat meters Landis + Gyr (Germany) , etc.

TECHNICAL CHARACTERISTICS OF THE MODULAR TRANSPORTABLE BOILER INSTALLATION "MTKU-1,4(P)"

| Name | MTKU-1,4(P) |

| Rated productivity*, tp/hour | 2.0 |

| Working steam pressure, MPa, no more | 0.8 (or 1.3 optional) |

| Number of boilers, pcs | 2 |

| Type of installed boiler | E-1.0-0.9 |

| Nominal boiler output, kp/h | 1.0 |

| Boiler efficiency, % | 91-natural gas 89-liquid fuel |

| Fuel | Natural gas, diesel fuel |

| Overall dimensions of the boiler room, number of blocks, weight | Provided upon completion of the questionnaire |

*-boiler rooms can be manufactured with other steam capacity according to the Customer's specifications.

DELIVERY SET INCLUDES:

| Boiler room on the basis of metal structures (boxes); |

| Two steam boilers E-1.0-0.9 for natural gas or liquid fuel operation; |

| Burner devices "Weishaupt" (Germany), "CibItalUnigas" (Italy) or others. |

| Pumping equipment (network and circulation pumps, make-up pumps, VPU pump); |

| Water treatment plant, taking into account the analysis of the Customer's source water; |

| Shut-off and control and safety fittings (at the option of the Customer); |

| Deaeration plant (atmospheric deaerator or chemical deaeration plant); |

| Chimney and other auxiliary equipment for reliable operation; |

Our modular transportable boiler plants MTKU for the generation of saturated steam

excel in the following industries:

- foam production;

- dairy industry;

- bakery industry;

- drilling rigs;

- oil extraction plants;

- asphalt plants;

- factories for the production of reinforced concrete products, etc.