Atmospheric deaerator DA-15/4 (15 m3/hour)

Monastyrishchensky plant of boiler equipment "Energometmash" offers an atmospheric deaerator DA-15/4 of its own production with a nominal capacity of 15 m 3 /hour.

Atmospheric deaerator of the "DA" series is designed to remove corrosive gases (oxygen and free carbon dioxide) from water, to feed steam boilers and make-up water for the heating system.

At the request of the Customer, the atmospheric deaerator can be supplied in a complete set (deaerator tank, deaeration column, vapor cooler, safety device) or in bulk (separately for components).

The BDA deaerator tank is a horizontal, cylindrical vessel with elliptical bottoms and nozzles for the inlet and outlet of the working medium, connection of pipelines and fittings, mounted on supports, one of which is fixed. A deaeration column is installed on the tank.

The KDA deaeration column is a cylindrical shell with an elliptical bottom, nozzles for supplying and discharging the working medium. The internal devices of the KDA deaeration column are made of stainless steel. When ordering, the body of the deaeration KDA column can be made of stainless steel.

Atmospheric deaerator DA-15/4 can be made to operate in two modes of operation:

- manual mode of operation , when the deaeration unit operates with a water seal.

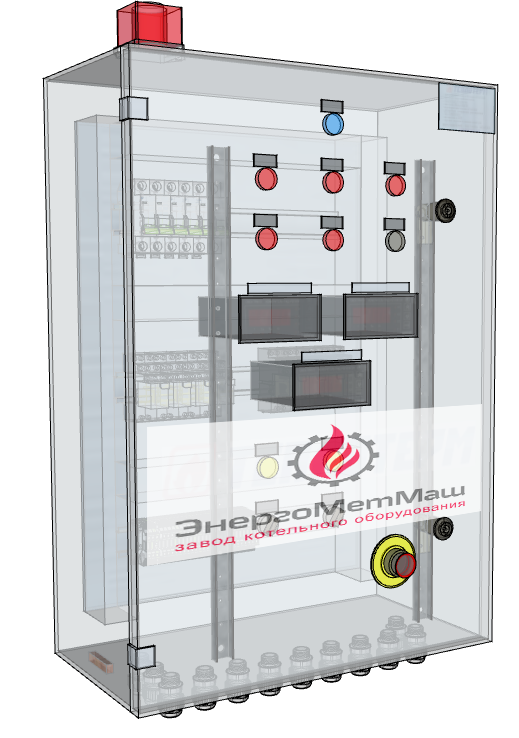

- automatic mode of operation , when atmospheric deaerators are equipped with control panels that implement the functions of automating level control in the deaerator and regulating the flow of heating and bubbling steam, as well as pressure regulators, control valves and safety valves.

The standard delivery set of the atmospheric deaerator DA-15/4 manufactured by Energometmash LLC includes:

- deaeration tank "BDA" volume at the choice of the customer. The deaeration tank is made with elliptical bottoms and has a manhole for inspection of internal surfaces. A bubbling device is provided at the bottom of the deaeration tank;

- deaeration column "KDA" with internal devices made of stainless steel;

- steam cooler "OVA" with heat exchange tubes made of stainless steel or brass (Customer's choice)

- safety device (water seal) . Only deaerators with simplified automation are supplied, when supplying atmospheric deaerators DA with control panels SHCHAD-e or SHCHAD-S, this device is not needed and is not included in the delivery set.

The optional delivery set of atmospheric deaerator DA-15/4 includes:

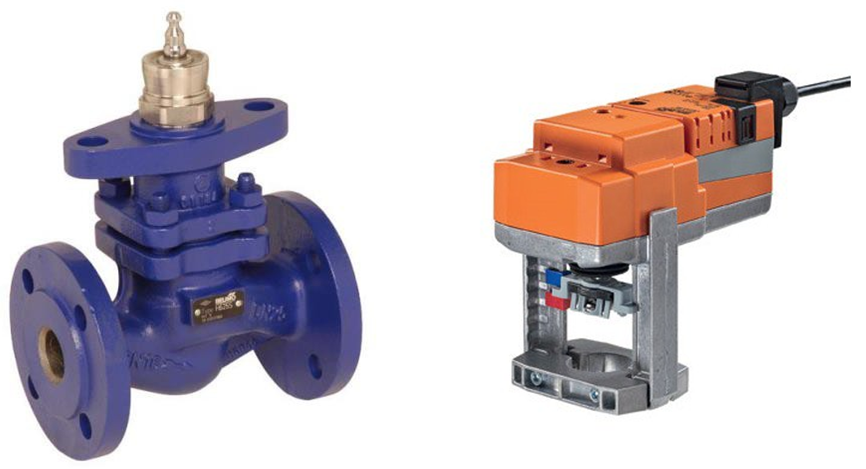

| Two-way flanged control valves Belimo (Italy) or Ari-Stevi (Germany) with actuators. These valves are used to supply steam and water. |  |

| Safety flanged valves Ari-Safe (Germany) provide relief of excess pressure of the working medium, if it exceeds 5% of the set value. |  |

| Ari-Predu (Germany) pressure reducing valves are designed to reduce and regulate high inlet pressure to lower outlet pressure. | |

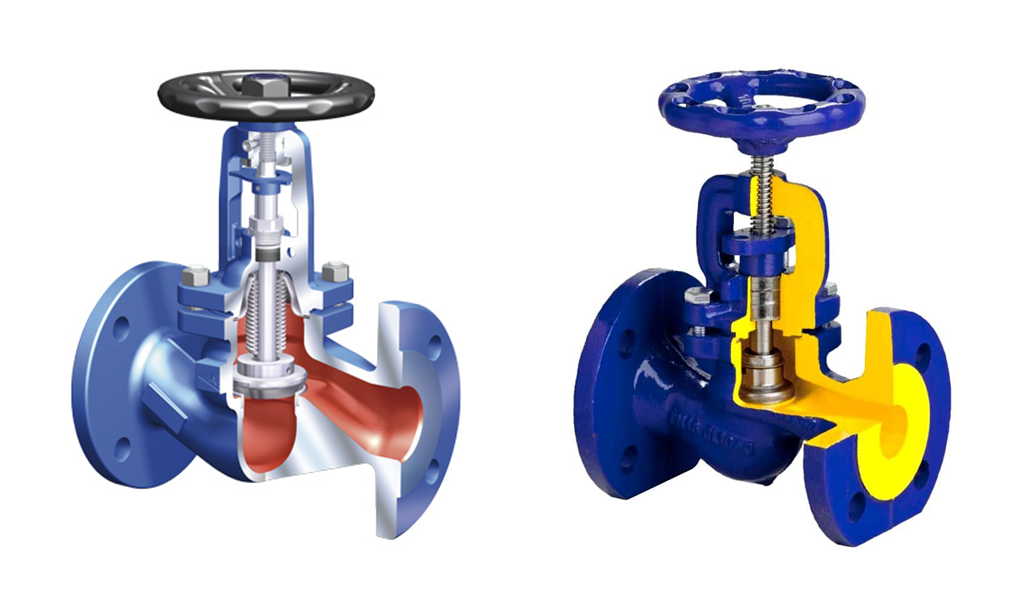

| Shut-off valves Ari-Faba-Plus (Germany) and/or Zetkama (Poland) . |  |

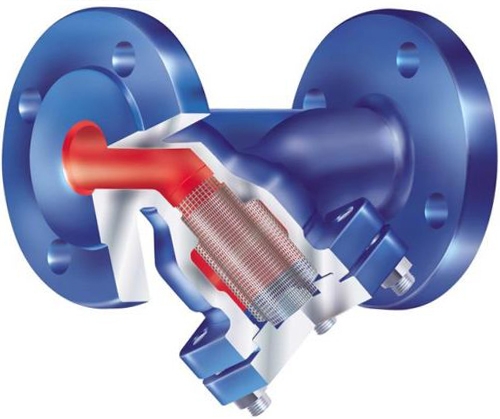

| Flange filters with fine mesh for steam Ari-Strainer (Germany) . |  |

| Liquid level indicator art.16.111 with a glass tube, stainless casing and stainless shut-off valves, capacitive level sensors Dinel (Denmark), steam pressure switches Fantini Cosmi (Italy) , steam pressure sensors OVEN and other measuring instruments. |  |

| Parameter name | DA-15 |

| The volume of the deaeration tank *, m 3 | 4.0 |

| Rated productivity, m 3 / h | 15.0 |

| Vapor cooler | OVA-2 |

| Capacity control range, % | 30-120 |

| Working pressure, bar | 0.2 |

| Test pressure, bar | 3.0 |

| Operating temperature, o C | 104.2±2 |

| Specific steam consumption, kg/t | 2.0 |

| Water heating in the deaerator, maximum, o C | fifty |

| Water heating in the deaerator, minimum, o C | 10 |

| The content of dissolved oxygen in the deaerated source water, mcg/kg, not more than | twenty |

| The content of free carbon dioxide in the deaerated source water, mg/kg, not more than | 10 |

| Bicarbonate alkalinity, mg-eq/kg, not less than | 0.4 |

| Dissolved oxygen content in deaerated water, mg/kg, max | footprints |

| The content of free carbon dioxide in deaerated water, mg/kg, not more than | absent |

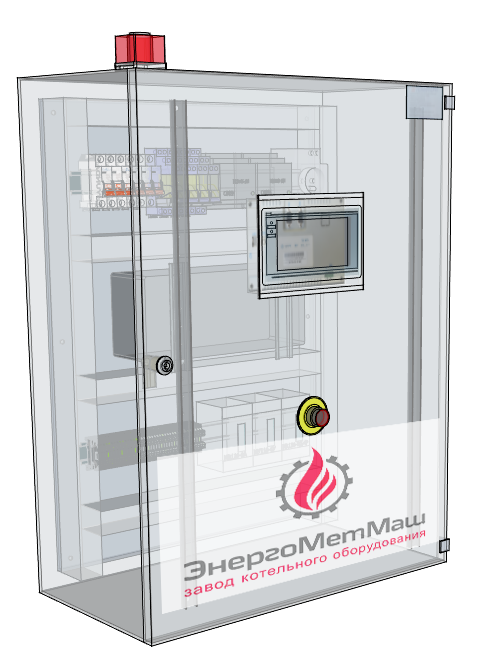

ShCHAD-E is an economical solution for automating the process of deaeration of water necessary for the operation of a steam boiler, provides reliable measurement, regulation, signaling, protection of technological processes in a deaeration plant. ShCHAD-S is a modern solution for automating the water deaeration process based on a microprocessor controller with an operator touch panel. |